As the summer temperatures remain in the “highly uncomfortable range”, there is a tendency for Facilities Operators to be thinking more about their HVAC Systems. However, the concerns of these systems shouldn’t just be limited to our hottest season. The key to keeping your operations running smoothly year-round can be found in partnering a consistent strategy with an experienced Service team. This will allow you to maximize the lifecycle of your Thermal equipment, a goal of every facility.

When new HVAC equipment is installed, you might be thinking that since its brand new, you can just let it do its thing and be out of sight and out of mind since it doesn’t need to be maintained. Beware of this mistake. After start-up, it’s good to plan ahead for a short-term periodic assessment to baseline important details like temperature consistency and humidity levels assuring acceptable water and air qualities. In subsequent years, keeping the infrastructure properly maintained will allow for a longer equipment lifespan. At this point, the objective is to keep an efficiently running system and looking for signs of potential component failures down the road. It’s all about being proactive, and keeping a watchful eye provided by factory trained technicians.

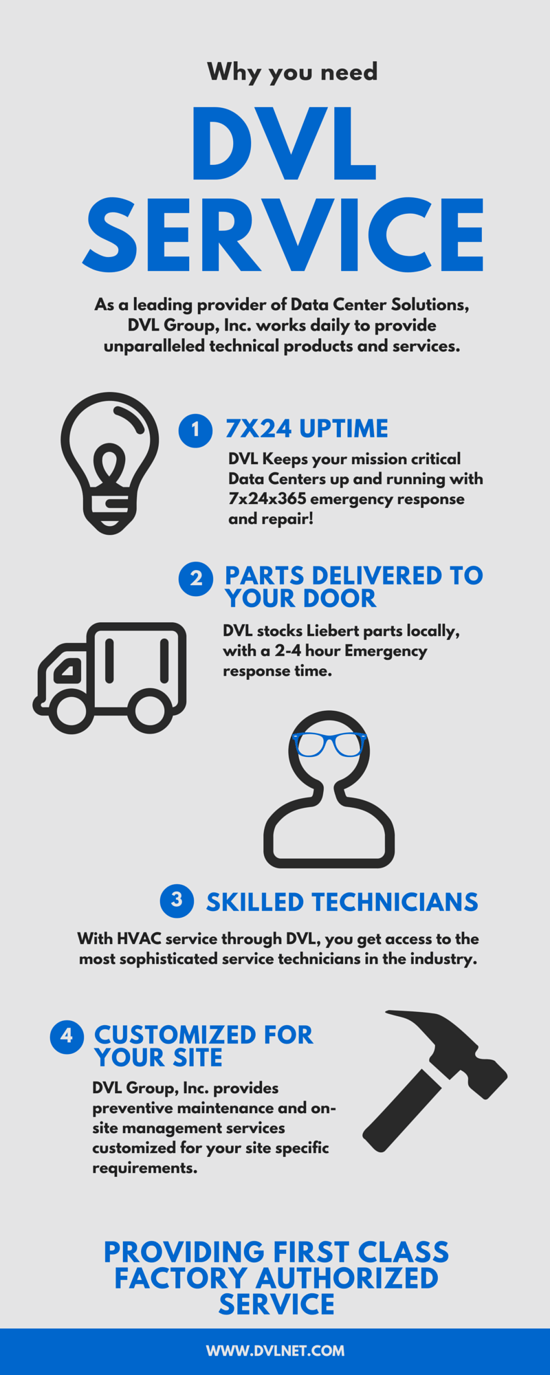

The technicians you have serve and monitor your HVAC are a big variable in this equation. You may have members of your team capable of some functions, but it is highly recommended that you outsource a company that specializes in your type of equipment. At DVL, all technicians are factory trained on Vertiv™ Liebert® solutions and improve their product knowledge through continuing education opportunities provided by internal programs at both Vertiv and DVL. While there are many companies providing HVAC service, utilizing the expertise of a company that is focused on the specifics of your facility can have positive, far-reaching outcomes including a better understanding of ‘normal operations’ to a keener eye for trouble-shooting.

Properly maintained equipment shouldn’t get to the point where it quits on you out of the blue. That’s why scheduled Preventative Maintenance is suggested on a quarterly basis. And in between those visits? Our DVL technicians aim to empower you, the equipment owner, to recognize potential issues that might lead to something worse down the line. Again, it’s all about being proactive. This can be achieved through simple steps such as walking the equipment footprint monthly or by checking certain monitored details at a predefined cadence.

These are just some of the tactics that can help extend an HVAC system’s lifespan, but how long of a service life are we talking? Sanja Motz, DVL’s Vice President of Service Operations, advises that a reasonable expectation is in the window of 12-15 years. Yes, this equipment (especially the Vertiv Liebert brands) is built to last many years; and our DVL services teams see some units out in the field that are 15 years strong “cooler than the other side of the pillow.” Still, even though your equipment might be mechanically sound, there does come a point of diminishing efficiency at which point you would be inevitably wasting money from how you manage the equipment. Less-efficient equipment will cost more money to operate, require more manpower to maintain, and will use more electricity compared to newer equipment being built today. If you consider rearchitecting to take advantage of the advancements in technology, which will yield greater efficiency, a proper analysis is recommended to review current performance details against any expected benefits of change.

Additionally, air quality is another major factor in HVAC operations and efficiency that you need to consider. This variable is impacted by both internal and external factors, and many people don’t think about half of their HVAC equipment being outdoors. The outside pieces of your infrastructure take a beating from the elements, atmosphere, animals, and even people. Indoor equipment brings focus onto the air filter, outdoor equipment emphasizes where the heat is being rejected. In the winter months it’s easier to reject the heat outside because the temperature differential is greater, but in the summer, when it’s hot and condensing temperatures around that same temperature, your equipment simply has to work harder to reject the heat. Therefore, this is the time when it’s most important to keep that equipment clean. Otherwise, compressors, which are usually the costliest part to replace and will require the most labor to install, start to fail.

Additionally, air quality is another major factor in HVAC operations and efficiency that you need to consider. This variable is impacted by both internal and external factors, and many people don’t think about half of their HVAC equipment being outdoors. The outside pieces of your infrastructure take a beating from the elements, atmosphere, animals, and even people. Indoor equipment brings focus onto the air filter, outdoor equipment emphasizes where the heat is being rejected. In the winter months it’s easier to reject the heat outside because the temperature differential is greater, but in the summer, when it’s hot and condensing temperatures around that same temperature, your equipment simply has to work harder to reject the heat. Therefore, this is the time when it’s most important to keep that equipment clean. Otherwise, compressors, which are usually the costliest part to replace and will require the most labor to install, start to fail.

Recently, Sanja sat down with Michael Hagan (Director of Thermal Services) and Matthew Hudspeth (Thermal Operations Lead Technician) on the DVL Power Hour webinar, Don't Lose Your Cool(ing) to discuss these topics, as well as their expert tips on how equipment owners can benefit from their own routine HVAC equipment checks. This includes providing insights into specific steps you can take in the summer to ensure outdoor debris and temperatures don’t hinder your critical infrastructure from operating at the highest possible reliability level.

In closing, be mindful that components of a successful maintenance program should include:

- Checking/Replacing filters

- Inspect Thermostat

- Inspect for duct leaks

- Lubricating Components

- Cleaning Evaporator and Condenser Coils

- Dampers, Fire, Virtual

- Drain Pans, Blower Motor, Heat Exchanger

- Refrigerant levels checked (leaks?), recharged (if needed)

- Inspect Electrical Components

- Fan motor and blades are inspected and lubricated

- Control box, switches, wiring, and safety controls are inspected

Columbus, Ohio [September 16, 2015] – Emerson Network Power, a business of Emerson, (NYSE: EMR) and the world’s leading provider of critical infrastructure for information and communications technology systems, today announced that the California Energy Commission (CEC) has approved the use in California data centers of the

Columbus, Ohio [September 16, 2015] – Emerson Network Power, a business of Emerson, (NYSE: EMR) and the world’s leading provider of critical infrastructure for information and communications technology systems, today announced that the California Energy Commission (CEC) has approved the use in California data centers of the