As Dave Rubcich (Vertiv’s VP, Key Accounts- Multi-Tenant) puts it, “you can’t be sustainable without being efficient,” and “if you’re going to have a sustainable data center you’re certainly going to be efficient—but you can be efficient without being sustainable.” He cautions they are two different terms not to be confused with one another.

Data center energy efficiency has varying driving factors for the range of effects yielded. When infrastructure and equipment are more energy efficient in the way they work, one of the most favorable results is the fact that operating costs will go down. Also, less repairs are needed, and less equipment too, which results in more open space in your data center. Lastly, but perhaps most importantly, the less energy that is used, the less of an impact you have on the environment and its natural resources. That’s where sustainability comes into the picture.

Sustainability is becoming more and more companies’ priority, but can have different meanings depending on how you’re looking at the issue. Overall, we are trying to sustain the levels of natural resources we have on the planet so as not to contribute to global warming, or even my some miracle make a dent in efforts to reduce it. To work towards this, data centers are striving to have absolutely no impact on the planet.

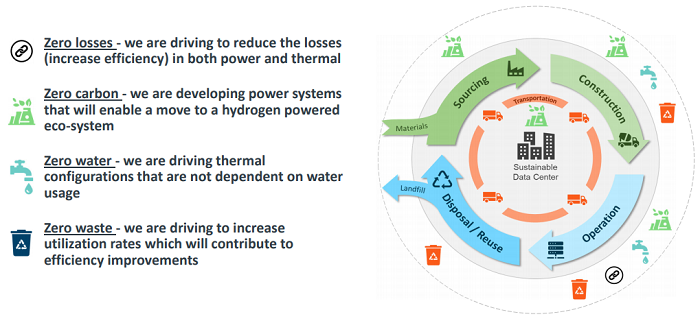

It is a dream of an ideal scenario. The way Vertiv sees it, sustainability means zero losses, zero carbon, zero water, and zero waste. “We’re nowhere near there today,” Rubcich admits, “But if we don’t start thinking about it, we can never get there.” So, is it plausible to truly not use any natural resources? Not today, but down the road, it’s the long-term goal, but only once real efforts have been made to chip away at the issue. Rubcich adds, “If you’re going to be carbon neutral or carbon negative, you’re not going to be using generators that are running on diesel fuels.” Alternative energy sources will be a must, going into the future.

Elsewhere, in the case of cooling equipment that rely on water, and therefore the equipment’s WUE (water usage effectiveness) is measured, there has been considerable movement away from certain any of these technologies that use a large supply water. Total water usage is becoming a leading factor for companies’ decision-making criteria for new equipment.

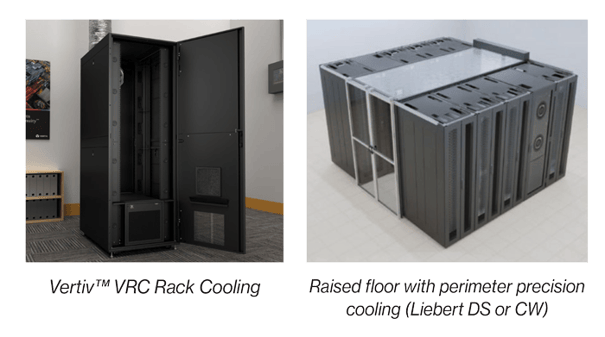

So, in what other way can end-users start to include sustainability strategies in the present-day operations of their data center? Rubcich notes that there are already a number of products readily available on the market today that are going to help improve overall efficiency of the data center and will help drive some of the sustainability goals. For example, pumped refrigerant as an economizer, as is the case with the Vertiv DX system, which doesn’t use any water.

Vertiv, along with many other companies are ramping up their efforts to be innovative with all types of technologies. Companies like Microsoft, Google, Amazon, and are able to make commitments for sustainability milestones in the future. For example, Microsoft is committed to use 100% renewables by 2025, and to be carbon-negative by 2030. While some companies’ sustainability goals seem like far off pipedreams, they are on the right path as they have brought on C-suite level sustainability officers to create and implement certain strategies to attain these results. As Rubcich points out, “when you’re hiring [someone to focus on sustainability] at that level, you’re committed to it.” And it is that commitment that will make it a reality.

To explore more of this subject with Dave Rubcich, we invite you to listen to our recent Podcast, The Cooler Side of Data Center Sustainability.

Additionally, air quality is another major factor in HVAC operations and efficiency that you need to consider. This variable is impacted by both internal and external factors, and many people don’t think about half of their HVAC equipment being outdoors. The outside pieces of your infrastructure take a beating from the elements, atmosphere, animals, and even people. Indoor equipment brings focus onto the air filter, outdoor equipment emphasizes where the heat is being rejected. In the winter months it’s easier to reject the heat outside because the temperature differential is greater, but in the summer, when it’s hot and condensing temperatures around that same temperature, your equipment simply has to work harder to reject the heat. Therefore, this is the time when it’s most important to keep that equipment clean. Otherwise, compressors, which are usually the costliest part to replace and will require the most labor to install, start to fail.

Additionally, air quality is another major factor in HVAC operations and efficiency that you need to consider. This variable is impacted by both internal and external factors, and many people don’t think about half of their HVAC equipment being outdoors. The outside pieces of your infrastructure take a beating from the elements, atmosphere, animals, and even people. Indoor equipment brings focus onto the air filter, outdoor equipment emphasizes where the heat is being rejected. In the winter months it’s easier to reject the heat outside because the temperature differential is greater, but in the summer, when it’s hot and condensing temperatures around that same temperature, your equipment simply has to work harder to reject the heat. Therefore, this is the time when it’s most important to keep that equipment clean. Otherwise, compressors, which are usually the costliest part to replace and will require the most labor to install, start to fail.